Johnstons of Elgin: The Craft Behind Luxury

A behind-the-scenes tour of Johnstons of Elgin's mill, discovering the heritage, skill, and craft that goes into every one of its creations.

Having the incredible opportunity of visiting the Johnstons of Elgin Mill in the Moray region of Scotland, I wanted to discover the heritage, skill, and craft that goes into the creation of their world-renowned cashmere and wool products. When thinking about the luxury industry, we are often quick to think of brand names and price points. The word 'luxury' itself is often overused and misused; a term penned for the wealthy. It is vital to be aware that authentic luxury design is about the product, its creation and the level of skill that it takes to produce the final piece. With my tour of the Elgin mill, I was able to experience these processes first-hand and discover why, over the past 200 years, Johnstons of Elgin still maintains the title as a leader in the industry.

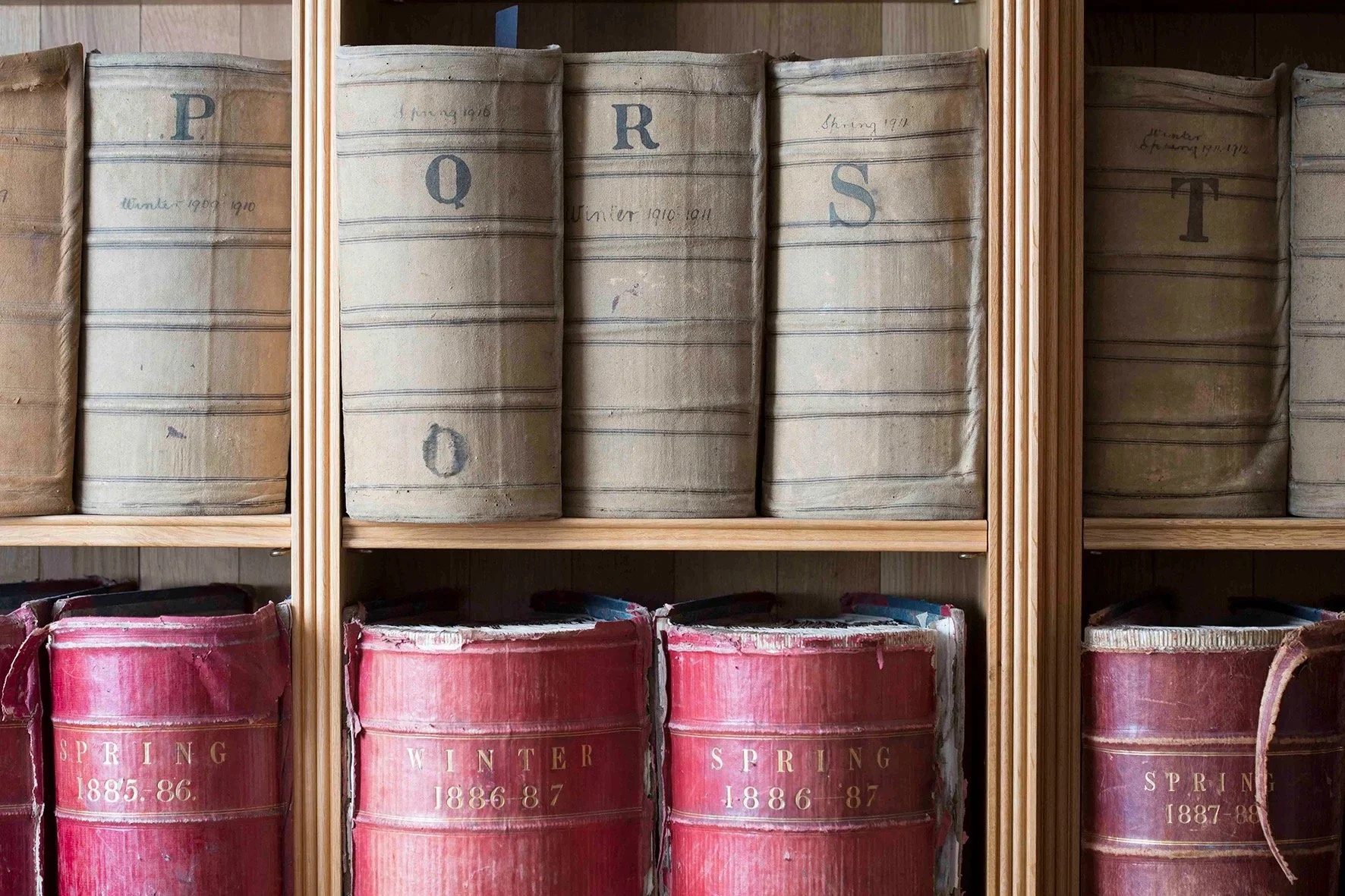

Visiting the archive room, it is clear to see the vast history of the brand. Super-size archive files hold fabric patterns, textiles and order books, some dating back to the early years of the business. This extensive documentation and impressive portfolio of designs not only write and record the past, but they also help shape the future, allowing the design team to refer back to, refine and even re-introduce original pieces. By using the past as a source of inspiration, the designers are able to stay true to company values and continue to proudly showcase Johnstons of Elgins heritage, all while helping to develop its future and write a new chapter. Having to be prised away from the fascinating swatches and relics of the archive room, it was time to tour the main mill.

The mill produces textiles from some of the finest fibres available. Cashmere from Mongolia and China, and, Merino Wool from Australia are cultivated to ensure they maintain their outstanding quality and sustainability. The brand also proudly boasts a scarf and stole collection that is woven from Vicuña wool; the finest wool in existence. Walking into the storage facilities, visitors are greeted by stacks of raw cashmere and Merino wool, wrapped and waiting patiently to be woven into garments and accessories. Johnstons of Elgin is the only manufacturer in Scotland with the capabilities of full-line production; taking fibres from their raw state and producing a finished product without it having to leave the site. The Elgin mill alone works with on average, 200 tonnes of raw cashmere a year. This cashmere is not only used to produce their own incredible collections of fashion accessories and textiles for the home, but also the lines of many well-known luxury fashion houses.

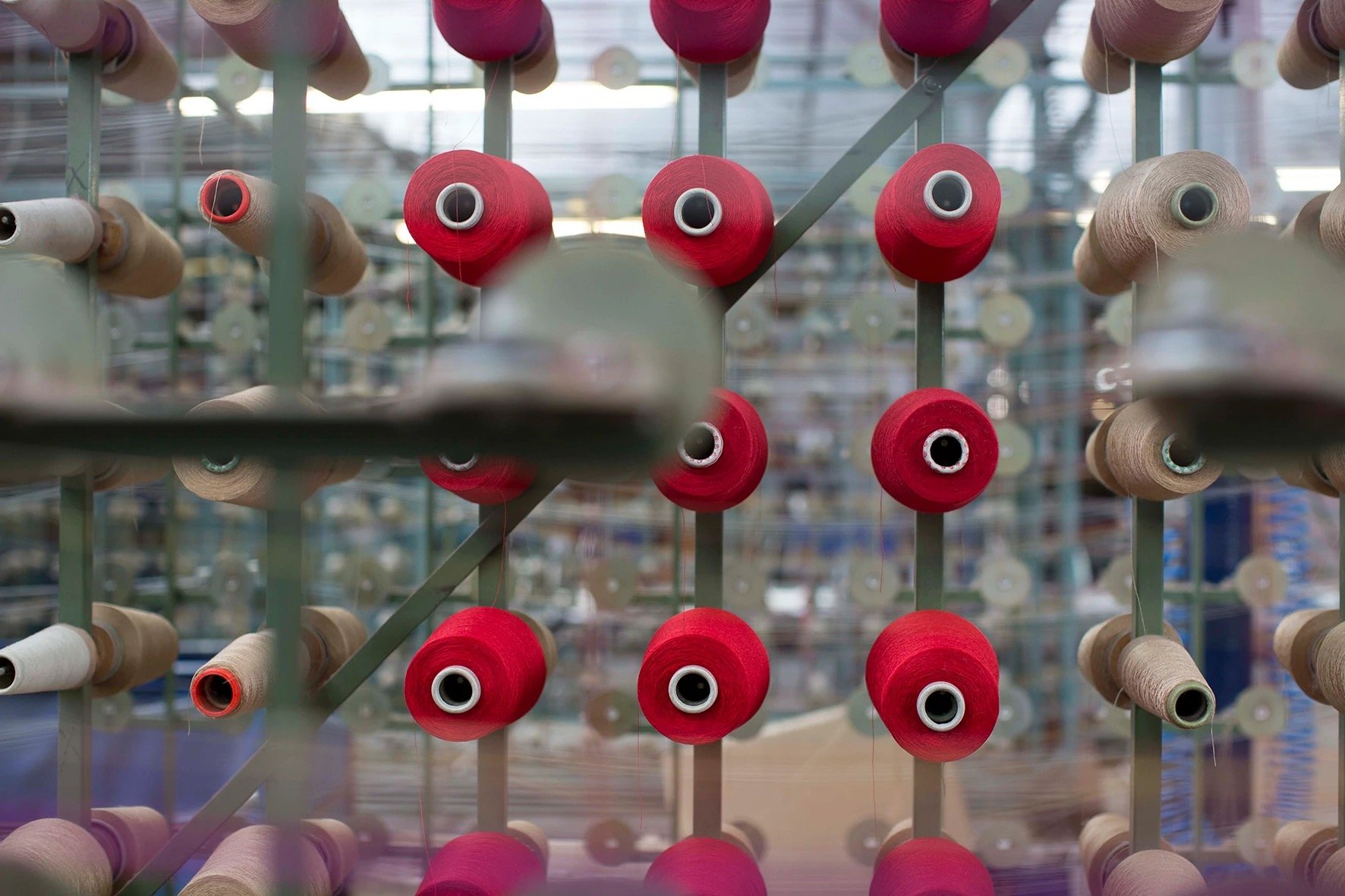

There are approximately thirty different processes that take place to transform raw natural fibre into a finished textile. Walking the production line, I was introduced to the many different stages the wool has to go through. To produce beautiful variations in colours, many batches have to be dyed in large vats. One of the most fascinating techniques used is with blending. To create the multi-coloured yarns that produce beautiful flecks of colour and texture in a garment, various coloured wools are funnelled into a blending room, where the fibres are essentially blown around simultaneously to blend and mix the fibres together. Visually it is a fascinating sight to witness and an unforgettable part of the tour. We then move on to carding process; mechanically disentangling and intermixing the fibres to produce a 'web-like' fine spread. This technique also aligns the individual fibres in parallel with each other in preparation for spinning into yarn.

Photography courtesy of Johnstons of Elgin

The most familiar yet complex part of the production is the weaving process. Surrounded by large machines clicking and swiping away, it was mesmerising watching the complex weaving patterns slowly filter through the mechanical looms. As technology advances, the mill continually upgrades itself, whether it be with higher capacity or faster machines. This was clear to see as different generations of looms worked alongside one another, producing a wide variety of designs. Even though the latest introductions look as if they have come out of a science fiction movie, one thing remains the same; the passion for the highest quality product. This involves every reel of fabric being meticulously checked by hand and signed off before it reaches its final destination.

I would like to thank the team for taking the time to show me around the Elgin Mill. It is so refreshing to see an iconic brand with over 200 years of history continuing to succeed in such a highly competitive market. Still family-owned, the brand manages to achieve a perfect balance of heritage and tradition, married with contemporary design and a passion for innovation and development. This is what makes this company so special and this is the true definition of luxury. When considering buying a beautiful throw for the home or a super-soft scarf for the winter season, think about the story behind its creation, and ensure that it is a Johnstons of Elgin design.